In the world of heavy industry, construction, and agriculture, a chain is more than just a piece of metal—it is the backbone of your operations. Whether you are lifting heavy loads, securing cargo, or integrated into an automated egg collecting machine, the quality of your ring chains determines both safety and efficiency.

With over 20 years of experience at Weifang FLT Chain Co., Ltd, we have seen how the right choice can save a company thousands of dollars, while the wrong choice can lead to costly downtime.

If you are looking for high-strength ring chains, here are the top 5 factors you must consider before making a purchase.

1. Material Grade and Steel Quality

The strength of a chain begins with the raw material. Not all steel is created equal. For industrial applications, you generally look for high-quality alloy steel.

-

Grade 80 and Grade 100: These are the industry standards for overhead lifting. They are made from heat-treated alloy steel that provides a high strength-to-weight ratio.

-

The FLT Advantage: We use premium steel that undergoes rigorous testing to ensure it meets international standards. Choosing the right grade ensures that the chain won’t stretch or snap under its rated load.

Pro Tip: Always ask your supplier for the material composition report to ensure you aren’t getting low-grade carbon steel for a high-stress job.

2. The Heat Treatment Process

You can have the best steel in the world, but without proper heat treatment, it won’t perform. Heat treatment is the process of heating and cooling the metal to change its physical properties—making it harder, stronger, and more durable.

A professional manufacturer uses controlled quenching and tempering. This creates a balance:

-

Hardness: To resist wear and friction.

-

Toughness: To absorb shocks without breaking (essential for moving parts in machinery).

Because we have 20+ years of production experience, our heat treatment protocols are perfected to ensure every link in the “Ring Chain” has uniform strength.

3. Surface Finish and Corrosion Resistance

Industrial environments are often harsh. Your chains might be exposed to rain, chemicals, or the humid environment of a poultry farm. Without the right surface protection, rust will weaken the chain from the inside out.

Common finishes include:

-

Black Oxide: Provides a sleek look and basic protection for indoor use.

-

Zinc Plated (Galvanized): Excellent for moisture resistance.

-

Hot-Dip Galvanized: The best choice for outdoor or corrosive environments.

When choosing a chain, consider where it will be used. A chain used in a coastal region or a chemical plant requires much higher corrosion resistance than one used in a dry warehouse.

4. Manufacturing Standards and Certifications

How do you know if a manufacturer is telling the truth about their quality? You look at their certifications. This is the “passport” for industrial products.

-

ISO9001: This proves the factory has a consistent quality management system. It means every batch of chains is produced the same way every time.

-

CE Certification: This is mandatory for the European market and indicates that the product meets high safety and environmental requirements.

At Weifang FLT Chain, our ISO9001 and CE certifications are a testament to our commitment to global standards. When you see these logos, you know the chain has been tested for Breaking Load Limits (BLL) and Working Load Limits (WLL).

5. Precise Dimensions and Pitch Consistency

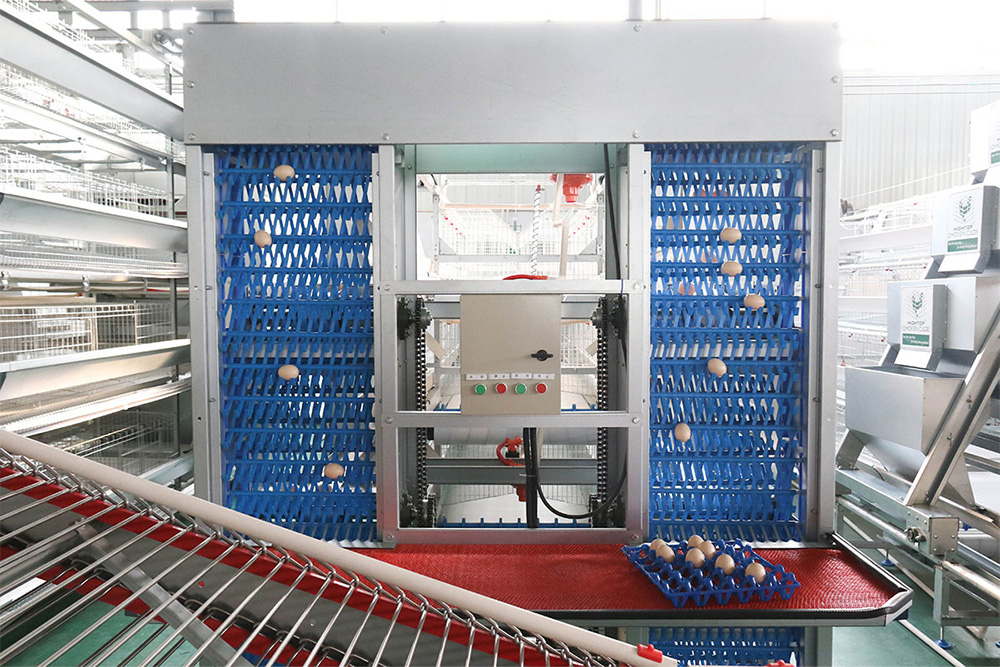

For many, a chain is just for pulling. But for others—like those using our Egg Collecting Machines—the chain is a precision component.

If the “pitch” (the distance between links) is inconsistent, the chain will:

-

Jump off the sprocket.

-

Cause the machine to vibrate.

-

Wear out the gears prematurely.

High-strength ring chains must be manufactured with high precision. Our automated production lines ensure that every link is identical, allowing for smooth operation in complex mechanical systems.

Why Choose Weifang FLT Chain Co., Ltd?

Selecting the right chain is about finding a partner who understands the technical details. We have exported our products to more than 30 countries, including the USA, Canada, Russia, and India. We understand the specific demands of different markets.

Our “Ring Chains” are designed to last, and our “Egg Collecting Machines” are built to help farmers modernize their operations with confidence.

Conclusion

Don’t settle for “cheap” chains. In the long run, a high-quality, certified ring chain is the most cost-effective investment you can make for your business. Focus on material, heat treatment, finish, certification, and precision.