When you are looking to buy industrial chains—whether for lifting, securing loads, or as part of an automatic egg collecting machine—the most common question we hear is: “Should I choose Galvanized or Stainless Steel?”

Choosing the wrong material can be a costly mistake. If the chain is too weak, it’s a safety hazard. If it rusts too quickly, you’ll spend a fortune on replacements.

At Weifang FLT Chain Co., Ltd, with over 20 years of experience and ISO9001 certification, we have manufactured “Ring Chains” for almost every environment imaginable. In this guide, we will break down the differences between these two popular options in simple terms.

1. What is a Galvanized Chain?

A galvanized chain is essentially a high-strength carbon steel chain that has been coated with a layer of zinc. This zinc layer acts as a “shield” to protect the steel underneath from oxygen and water, which cause rust.

There are two main types of galvanization:

-

Electro-Galvanized: A thin, shiny layer of zinc. It looks great but offers basic protection.

-

Hot-Dip Galvanized: The chain is dipped into molten zinc. This creates a much thicker, duller gray coating that is incredibly tough.

The Pros:

-

Cost-Effective: Galvanized chains are significantly cheaper than stainless steel.

-

High Strength: Because the core is carbon steel, these chains are excellent for heavy-duty pulling and lifting.

-

Good Corrosion Resistance: Hot-dip galvanized chains can last a long time in outdoor environments.

The Cons:

-

The Coating Can Wear Off: If the chain is constantly rubbing against hard surfaces, the zinc layer can scrape off, exposing the bare steel to rust.

2. What is a Stainless Steel Chain?

Unlike galvanized chains, stainless steel is not a “coating.” It is a solid alloy. The anti-rust properties are built into the metal itself, usually through the addition of Chromium and Nickel.

The most common grades used in industry are Grade 304 (standard) and Grade 316 (marine grade).

The Pros:

-

Superior Rust Resistance: Stainless steel will not rust even if the surface is scratched. It is the king of durability in wet or salty environments.

-

Aesthetic Appeal: It stays bright and shiny for years, which is important for architectural or high-end equipment.

-

Chemical Resistance: It can withstand harsh cleaning chemicals, making it ideal for food processing or poultry farms.

The Cons:

-

Higher Price: It can be 3 to 5 times more expensive than galvanized steel.

-

Slightly Lower Strength: Generally, for the same thickness, a stainless steel chain has a lower “Working Load Limit” than a high-strength galvanized alloy chain.

3. How to Choose? Ask These 3 Questions

To help you decide, we recommend our clients at Weifang FLT Chain ask themselves these three questions:

A. Where will the chain be used?

-

Indoor/Dry Warehouse: Use Electro-Galvanized.

-

Outdoor/Construction Site: Use Hot-Dip Galvanized.

-

Near the Ocean/Saltwater: You must use Grade 316 Stainless Steel.

-

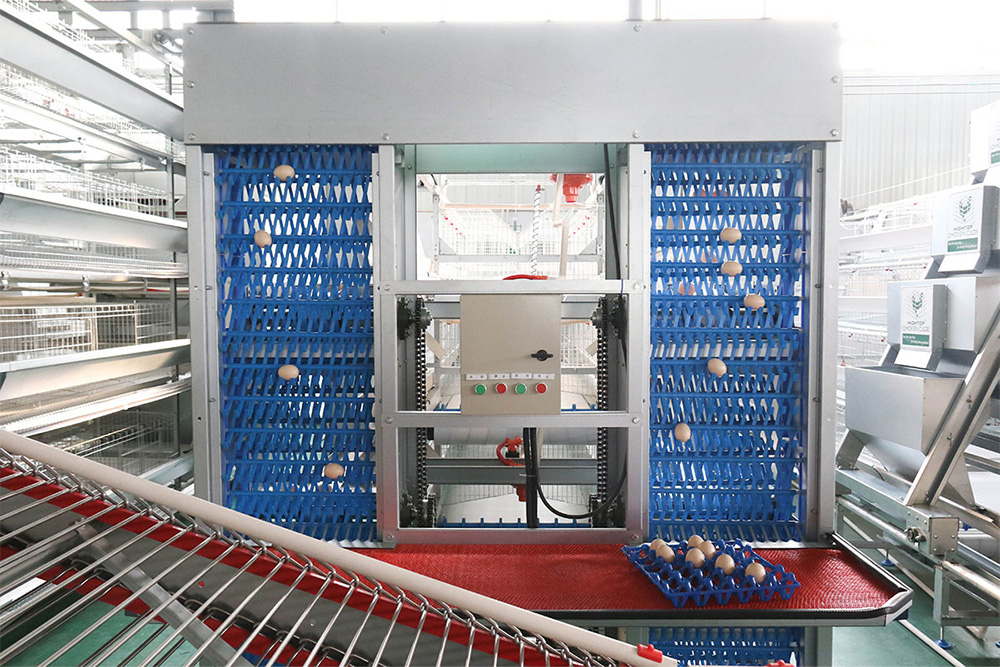

Inside a Poultry Farm (Egg Collecting): We often recommend Stainless Steel or high-quality Galvanized chains because of the humidity and ammonia from bird droppings.

B. Is it for heavy lifting?

If you are lifting several tons of equipment, a High-Strength Galvanized Alloy Chain (Grade 80) is often the better choice because it provides the necessary breaking strength at a lower price point.

C. What is your budget?

If you are building a large-scale project and need 5,000 meters of chain, Hot-Dip Galvanized offers the best balance of “Protection vs. Price.” If you only need a small amount for a high-moisture area, Stainless Steel is a “buy it once and forget it” solution.

4. Why the Manufacturing Quality Matters

Regardless of the material you choose, the quality of the Ring Chain depends on the factory. A poorly galvanized chain will have “bubbles” in the coating that flake off. A poor-quality stainless steel chain might not actually contain enough Nickel, leading to “mystery rust” within months.

At Weifang FLT Chain, we ensure:

-

Uniform Coating: Our hot-dip process ensures every link is fully protected.

-

Certified Grades: We provide material certificates so you know exactly what is in your steel.

-

CE Standards: Our chains meet European safety requirements, ensuring they won’t fail under their rated load.