An Automatic Egg Collecting Machine is a significant investment for any poultry farm. When it runs smoothly, it saves you hours of labor and protects thousands of eggs. However, like any hardworking piece of industrial machinery, it requires regular “TLC” (Tender Loving Care).

At Weifang FLT Chain Co., Ltd, we have been manufacturing these systems and high-strength Ring Chains for over 20 years. We know that a well-maintained machine can last twice as long as one that is neglected.

Here are our top professional tips to help you extend the lifespan of your system and keep your “win-win cooperation” profitable for years to come.

1. Keep the Driving Chains Lubricated

The “heartbeat” of your egg collection system is the chain drive. These chains work in dusty environments, which can suck the moisture out of metal parts and cause friction.

-

The Routine: Check your driving chains every week. They should be clean and slightly oily to the touch.

-

The Solution: Use a high-quality lubricant. Avoid “sticky” oils that attract dust, as this can create a “grinding paste” that wears down the metal.

-

Pro Tip: Since we specialize in high-strength Ring Chains, we ensure our chains are heat-treated for durability. However, even the strongest steel needs lubrication to prevent “metal-on-metal” wear.

2. Check the Tension Regularly

Over time, all chains and conveyor belts will stretch slightly due to constant tension and temperature changes.

-

The Danger: If a chain is too loose, it can jump off the sprocket, causing the machine to jam and potentially breaking eggs—or worse, damaging the motor. If it is too tight, it puts unnecessary stress on the bearings.

-

The Fix: Inspect the tension monthly. Adjust the tensioning bolts so there is a slight “give” but no sagging. A properly tensioned system runs quieter and uses less electricity.

3. Clean the Sensors and Limit Switches

Modern automatic systems rely on sensors to know when to start and stop. In a poultry house, dust, feathers, and cobwebs are everywhere.

-

The Problem: If a sensor is covered in dust, it might not “see” the eggs or the collection tray. This can lead to overflows or system crashes.

-

The Action: Use a soft, dry cloth or a can of compressed air to clean all optical sensors and limit switches every few days. It takes only 5 minutes but can prevent hours of downtime.

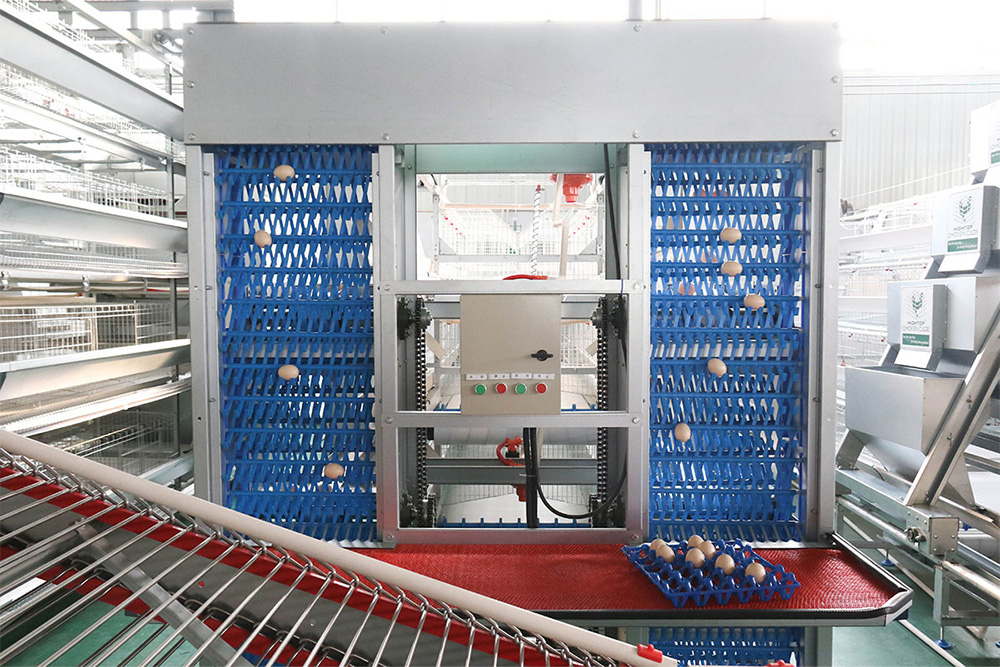

4. Monitor the “Egg Soft Landing” Areas

The points where eggs move from the nest to the belt, or from the belt to the elevator, are the most critical for preventing breakage.

-

Inspection: Check the soft plastic fingers or rubber buffers at these transfer points. Over time, these parts can become brittle or dirty.

-

Maintenance: Clean these areas to remove any broken egg residue. Dried egg yolk is like glue—it can trap dust and create a rough surface that cracks the next batch of eggs.

5. Annual Deep Inspection of Motors and Gearboxes

While daily and weekly checks keep you running, an annual “Deep Dive” is essential for long-term health.

-

Listen to the Machine: Unusual squeaking, grinding, or humming sounds are early warning signs of bearing failure.

-

Check for Heat: If a motor feels excessively hot to the touch, it may be overworked or have a faulty electrical connection.

-

The FLT Standard: Because our machines are CE Certified, they are built to high safety standards. However, checking the gearbox oil level once a year is a simple way to ensure the internal gears remain in perfect condition.

6. Train Your Staff

The machine is only as good as the person operating it. Many mechanical failures are actually caused by “human error,” such as forcing a jammed belt or ignoring a warning light.

-

Knowledge is Power: Ensure every worker knows how to hit the Emergency Stop button and knows the basic “Daily Checklist.”

-

FLT Support: We provide clear manuals and technical support to our clients in over 30 countries to ensure their staff feels confident using our equipment.

Why Maintenance Saves You Money

It is tempting to “save time” by skipping maintenance, but the costs of a breakdown are always higher:

-

Repair Costs: Emergency parts and overnight shipping are expensive.

-

Product Loss: If the machine stops, eggs pile up, leading to high breakage rates.

-

Labor Chaos: If the machine fails, you suddenly need 5 people to do manual collection, which ruins your labor budget.