In the poultry industry, the two biggest challenges for farm owners are egg breakage and rising labor costs. Every broken egg is lost profit, and every hour spent on manual collection adds to the operational expense.

If you are still relying on manual labor to collect eggs, you are likely losing money every single day. Modern technology has provided a solution: the Automatic Egg Collecting Machine.

At Weifang FLT Chain Co., Ltd, we have spent over 20 years perfecting our machinery to help poultry farms transition from traditional methods to high-efficiency automation. In this article, we will explore how investing in an automatic system can transform your farm’s profitability.

The Hidden Cost of Manual Egg Collection

Many small to medium-sized farms believe that manual collection is “cheaper” because they don’t have to buy expensive machinery. However, manual collection comes with hidden risks:

-

High Breakage Rate: Human hands, even the most careful ones, make mistakes. Eggs are dropped, or baskets are bumped. In a manual system, the breakage rate can be as high as 3% to 5%.

-

Labor Dependency: Finding reliable workers is becoming harder and more expensive. Manual collection is a repetitive, 365-day-a-year job.

-

Stress on Hens: Frequent human entry into the chicken house can stress the birds, which leads to lower egg production over time.

1. How the Machine Reduces Breakage Rates

The primary goal of an automatic egg collecting machine is “Gentle Handling.” Here is how the technology protects your product:

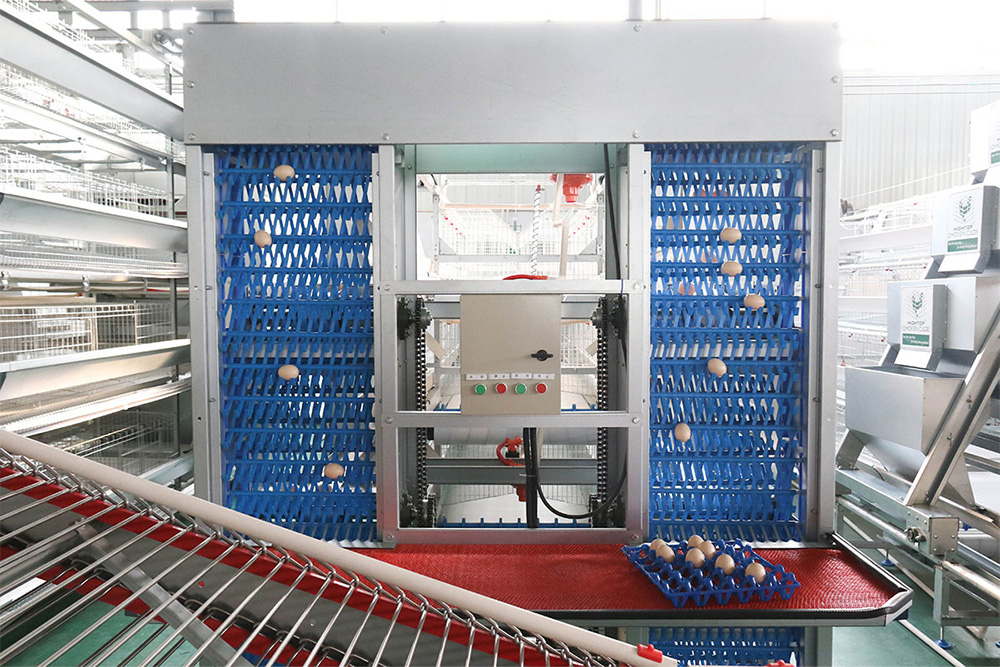

Soft Conveyor Belts

Instead of hard plastic or metal buckets, our machines use high-quality, anti-static conveyor belts. These belts move at a consistent, controlled speed. The eggs roll gently from the nest onto the belt, avoiding any hard impact.

Precision Transfer Points

Most breakage happens when eggs move from one level to another. Our systems feature “buffer devices” that act like cushions. They ensure that even when eggs are being moved from high tiers to the main collection area, they never collide with each other.

Stable “Ring Chain” Technology

As a specialist in Ring Chains, Weifang FLT ensures that the driving system of the machine is incredibly smooth. Unlike low-quality chains that might jerk or vibrate, our high-precision chains ensure a steady flow, which is critical for keeping fragile shells intact.

2. Slashing Labor Costs by Up to 80%

Labor is one of the highest ongoing expenses for any farm. Here is how automation changes the math:

-

Single-Person Operation: A large poultry house that previously required 4 or 5 workers for manual collection can now be managed by just one person. The machine does the “heavy lifting” and the traveling; the worker simply monitors the process.

-

Time Efficiency: Manual collection is slow. An automatic system can collect thousands of eggs in a fraction of the time. This allows your staff to focus on more important tasks, such as bird health, nutrition, and facility maintenance.

-

Consistency: A machine doesn’t get tired, doesn’t take holidays, and works exactly the same way at 6:00 AM as it does at 6:00 PM.

3. Improving Hygiene and Egg Quality

Dirty eggs are worth less than clean ones. Manual collection often leads to “secondary contamination” because workers’ hands or dirty baskets touch the shells.

-

Less Human Contact: The less a human touches an egg, the cleaner it stays.

-

Rapid Removal: Automatic machines move eggs away from the manure and dust of the chicken house almost immediately after they are laid. This results in a much higher percentage of “Grade A” clean eggs.

4. Why CE and ISO9001 Certifications Matter

When you buy an automatic egg collecting machine, you are making a long-term investment. You need to know that the machine won’t break down after six months.

At Weifang FLT Chain Co., Ltd, our machines carry CE Certification. This means they meet strict safety and performance standards required in Europe and North America. Our ISO9001 certification ensures that every machine we ship is built with the same high-quality components and rigorous testing.

When you choose a certified manufacturer, you are choosing a machine with:

-

Higher durability (longer lifespan).

-

Lower noise (to keep the hens calm).

-

Safety features for the operators.

5. Global Success: Exported to 30+ Countries

Our equipment is already working on farms in the United States, Canada, Russia, Brazil, and Southeast Asia. We understand that a farm in the Middle East has different climate challenges than a farm in Canada.

Our machines are built with high-strength materials that resist corrosion and heat, ensuring they perform in any environment. With 20 years of production experience, we don’t just sell you a machine; we provide a win-win cooperation strategy.

Conclusion: Is it Time to Upgrade?

If you are looking to grow your business, you cannot do it by simply hiring more people. You must increase your efficiency.

By reducing egg breakage and cutting labor costs, an Automatic Egg Collecting Machine typically pays for itself within the first 12 to 18 months of operation. From that point on, the savings go directly into your pocket as profit.